Fighting F.O.G

What is F.O.G?

F.O.G is Fats, Oils and Grease, which occurs from the process of cooking and food preparations.

Many cities and municipalities have been fighting this issue for many years and have implemented policies and procedures to combat this problem.

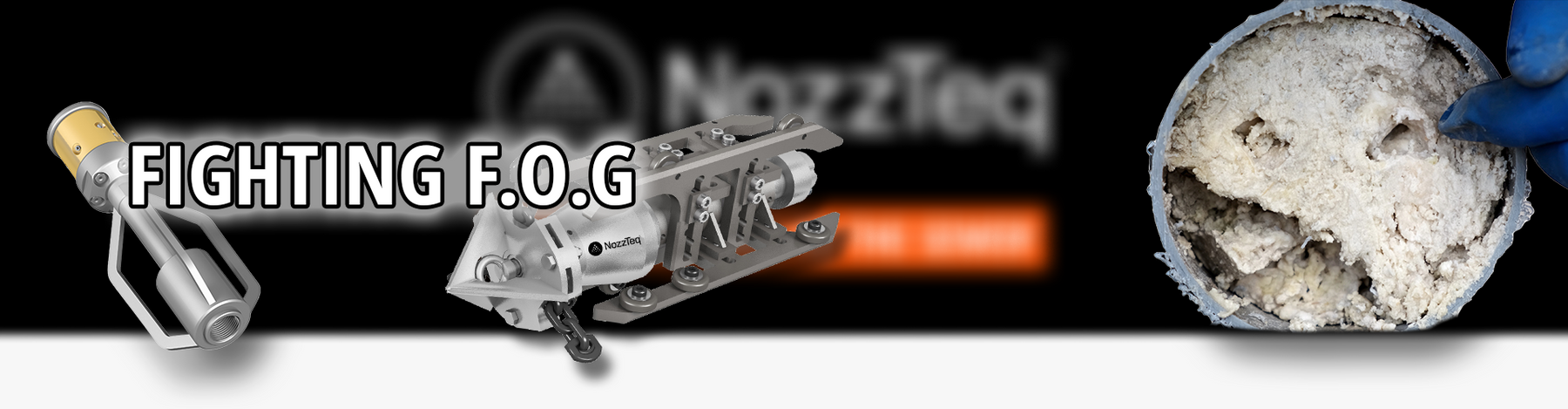

How is it formed, well by pouring cooking oils and grease along with food particles down the drains, which will eventually form grease blockages as the oils and grease solidify and cause the food particles to adhere to the not just the piping in your home, and inside the laterals and eventually inside the main lines. This will cause blockages that can slow the flow of wastewater and eventually blocking the flow altogether.

Some of the ways to combat this is to not pour grease, oil, and food particles down the drain. But when this happens over time the drain lines will become clogged and the only means of correcting the problem is to mechanically clean the lines.

We recommend a spinning nozzle such as the BL Spinner™, or for hardened grease the Lumberjack®.

The BL Spinner™ is a fast-rotating nozzle with jets angled at 90 and 45 degree, and 4 thrusting jets, to push it down the line and also to flush the emulsified grease. When using the Spinner, we recommend the use of a sled to help center the nozzle in the line and this also allows the water pattern to be closer to the host pipe which in turn provides a strong water stream to break up the grease blockages. The BL Spinner™ is constructed of Brass and Stainless steel. This means there is no maintenance, no oil, no bearings spinner. Just a simple rising when the use has been completed is all that is required. There are several sizes of the BL Spinner™, depending on the size of the lines that need to be cleaned.

For that hardened grease blockage in the we recommend the Lumberjack®.

The Lumberjack® is a High-speed low torque cutter, with a sharpened front knife and chains.

The Lumberjack® can rotate up to 25,000 RPM, based on the GPM of the jetting unit. This cutter will break up the grease blockages and pulverize the grease, which can then be flushed back to the jetter unit or allowed to flow towards the wastewater treatment plant.

The Lumberjack® requires little to no maintenance since it is designed with 2 grease filled bearing that ride on a hardened stainless-steel shaft. No oiling or grease is required. We recommend that a simple washdown with clean water after each use.

The Lumberjack® is available in 5 different sizes available from 3” to 36”.